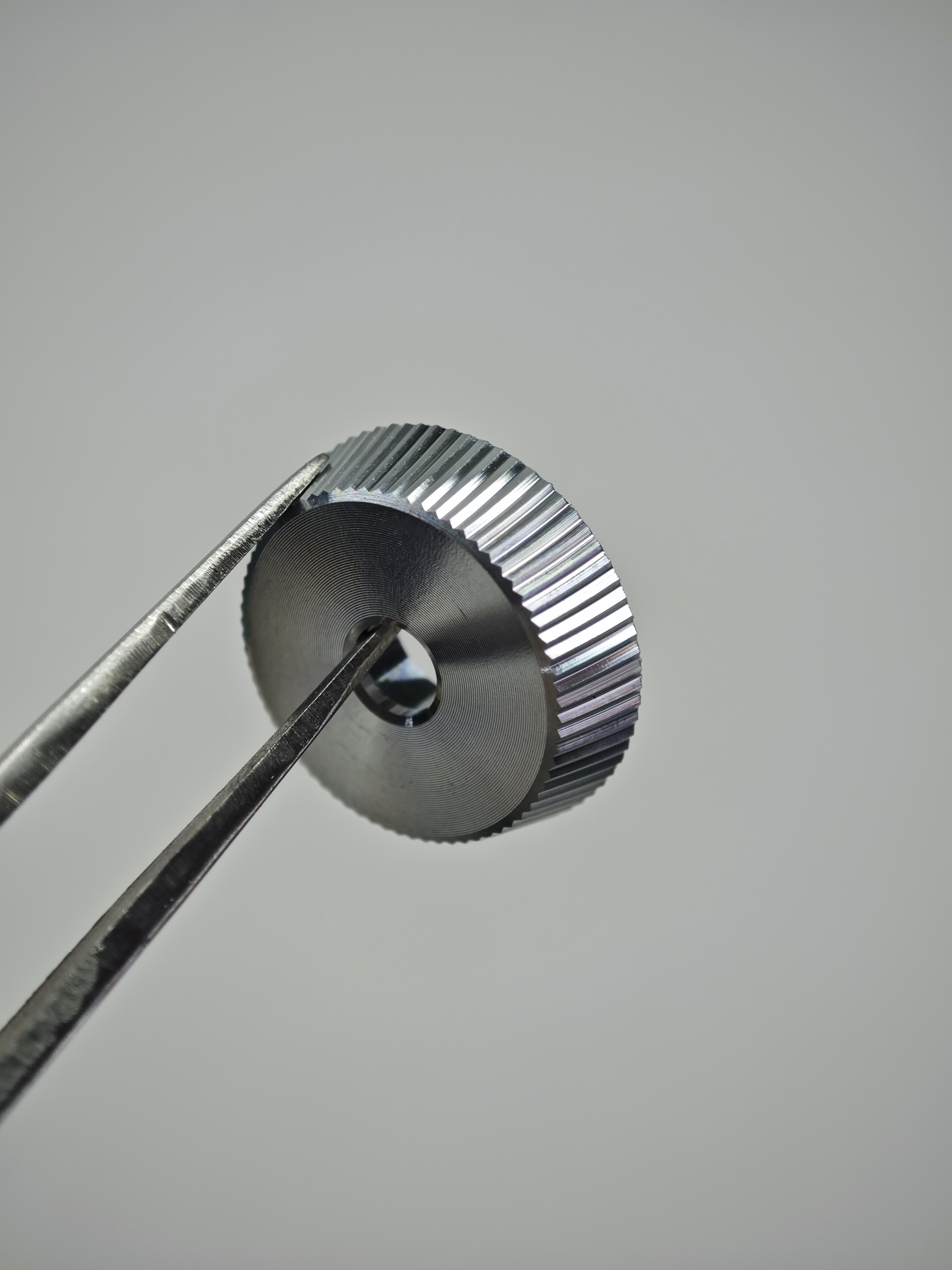

This CNC-turned component features a straight (striped) rolled knurling pattern, providing a directional grip for enhanced usability in mechanical and ergonomic applications. The precision-knurled texture is achieved through a cold-forming process that displaces material rather than cutting it, ensuring a durable, burr-free finish.

Key Features:

? Straight Rolled Knurling – Linear grooves for secure, directional grip.

? CNC Turning Precision – Tight tolerances (±0.005" or better) for consistent quality.

? Burr-Free Finish – Smooth, rolled edges for improved handling.

? Material Flexibility – Compatible with aluminum, stainless steel, brass, and engineered plastics.

? Customizable Pitch & Depth – Fine, medium, or coarse knurling based on application needs.

Common Applications:

• Thumb Screws & Adjustment Knobs – Tactile grip for precise control.

• Shafts & Couplings – Improved torque transmission and anti-slip performance.

• Medical & Dental Instruments – Ergonomic handles for better manipulation.

• Automotive Controls – Gear shifters, handbrake levers, and dashboard dials.

• Industrial Handles & Levers – Slip-resistant operation in machinery.

Technical Specifications:

• Process: CNC turning with secondary knurling operation

• Knurling Type: Straight/rolled (non-cut, deformation-based)

• Tolerances: Standard ±0.005" (custom tolerances available)

• Surface Finish: Smooth, deburred (optional polishing or plating)

Advantages Over Cut Knurling:

• Higher Durability – Rolled knurling work-hardens the surface for better wear resistance.

• No Material Loss – Maintains part integrity without generating chips.

• Cleaner Finish – No sharp edges or burrs, reducing post-processing.

Available in custom diameters, lengths, and knurling specifications—contact us for tailored solutions!