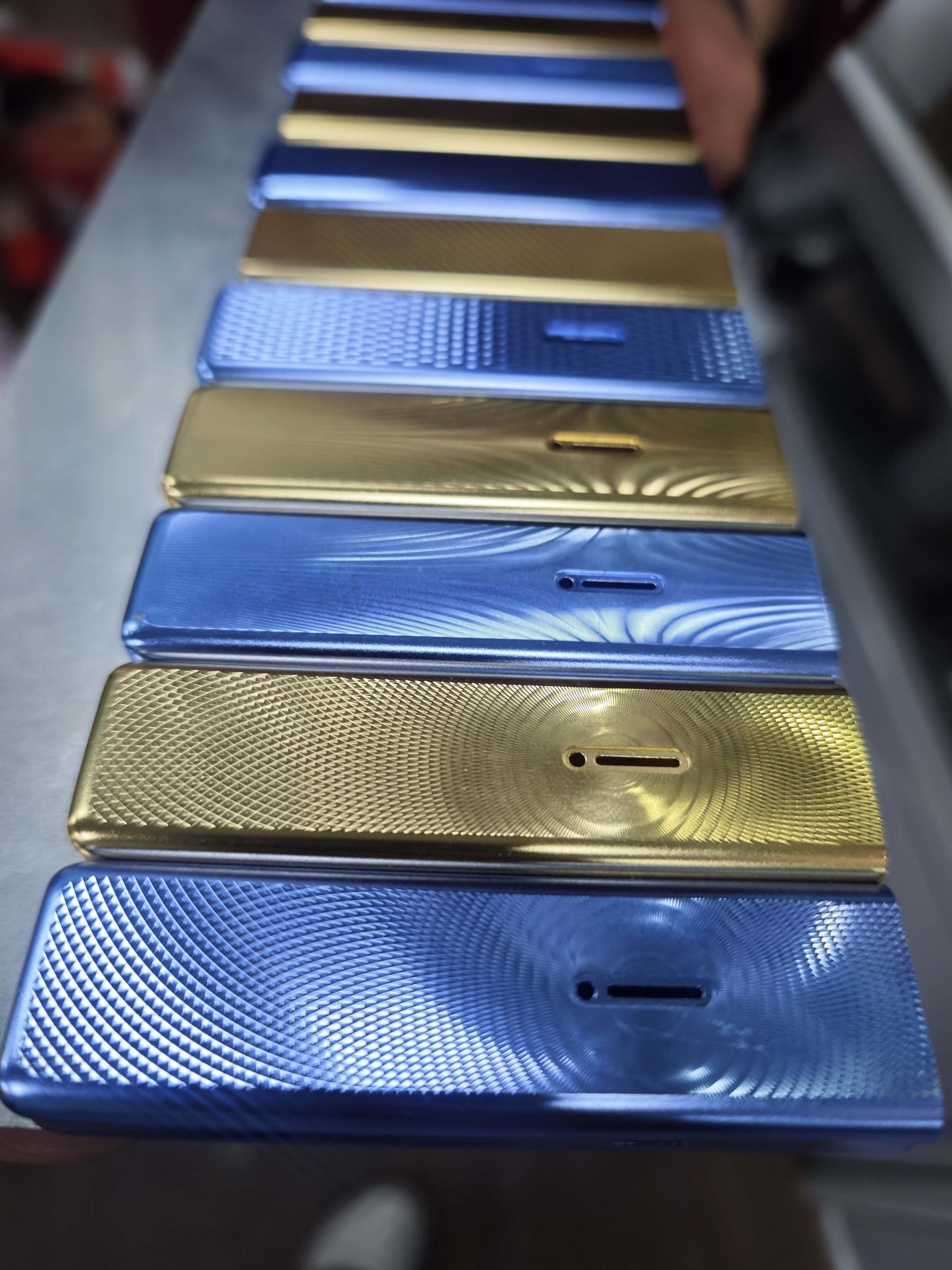

Precision Laser Engraved Decorative Patterns on Metal

Transform your metal components into works of art with our high-precision laser engraving services. We permanently etch intricate decorative patterns—from geometric designs and organic textures to logos and custom artwork—directly onto the surface of metals like stainless steel, aluminum, brass, and titanium.

Unlike prints or coatings that can fade, laser engraving removes material or alters its microstructure at a micron level, creating a contrast that is both visually striking and exceptionally durable. The result is a sophisticated, wear-resistant finish that integrates seamlessly with the part itself, enhancing both aesthetics and perceived value.

Key Benefits:

• Unmatched Detail: Achieve fine lines, complex gradients, and photorealistic images with pinpoint accuracy.

• Permanent & Durable: The pattern becomes part of the metal, resisting abrasion, chemicals, and outdoor exposure.

• Design Flexibility: Perfect for flat, curved, or irregular surfaces. Ideal for both one-off prototypes and high-volume production runs.

• Clean & Contactless: A dry, non-contact process that requires no inks or tools, ensuring consistency and a contaminant-free finish.

2. Marketing / Brand Voice Snippets

For a premium brand:

Elevate Your Product's Narrative.

Move beyond the ordinary. Our laser engraving imbues your metal parts with a timeless, tactile elegance. Each engraved line tells a story of craftsmanship, creating an emotional connection and an unmistakable signature of quality.

For a technical/industrial brand:

Engineered Aesthetics.

Where form meets function. We apply decorative patterns with the same precision used for technical markings. Enhance ergonomic grip, brand recognition, and user experience without compromising the integrity of your component.

Short Taglines:

• Art, Etched in Metal.

• Surface Deep Beauty.

• Custom Patterns. Permanently Impressed.

• The Lasting Impression.

3. Applications & Use Cases

• Consumer Electronics & Goods: Add branded textures, serial numbers, or artistic designs to premium phone cases, laptops, water bottles, pens, and tools.

• Automotive & Aerospace: Create non-slip surfaces, brand interior trim, or add subtle decorative accents to dashboard panels, gear shifts, and nameplates.

• Architecture & Interior Design: Incorporate custom patterns into elevator panels, door handles, signage, kitchen backsplashes, and decorative tiles.

• Giftware & Awards: Produce heirloom-quality trophies, personalized jewelry, corporate gifts, and commemorative plaques with exquisite, lasting detail.

4. Technical Process Summary

How It Works: A focused laser beam interacts with the metal surface, either by ablating (vaporizing) material to create depth or by inducing an oxide layer to change its color (e.g., creating black marks on stainless steel).

Common Metals & Effects:

• Stainless Steel: Can produce dark black, white, or etched silver finishes.

• Anodized Aluminum: Selectively removes the colored anodized layer to reveal the silver metal beneath.

• Brass & Copper: Creates high-contrast, permanent marks.

Design File Preparation: Vector files (.ai, .dxf, .svg) are ideal for clean lines and shapes. High-resolution bitmap images (.png, .bmp) can be used for photographic content.