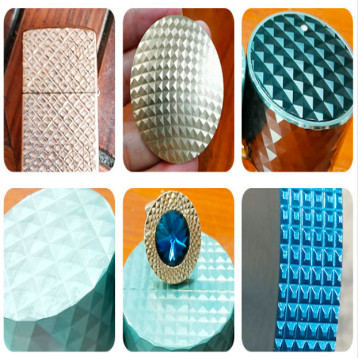

This CNC machined part features a high-precision diamond knurling pattern, providing an enhanced grip and a professional, textured finish. Ideal for applications requiring secure handling, the diamond knurling is machined with consistent depth and spacing for optimal functionality and aesthetics.

Key Features:

? Diamond Knurling Pattern – Crosshatched texture for superior grip in all directions.

? Precision CNC Machined – Ensures uniform knurling depth and repeatability.

? Durable & Wear-Resistant – Suitable for high-use applications.

? Customizable – Available in various pitches (fine, medium, coarse) and diameters.

? Multiple Material Options – Aluminum, stainless steel, brass, titanium, and engineered plastics.

Common Applications:

• Adjustment Knobs & Handwheels – For machinery and industrial equipment.

• Tool Handles & Grips – Improves control in hand tools and instruments.

• Automotive Components – Gear shift knobs, control dials, and levers.

• Aerospace & Defense – Tactile grip surfaces for controls and fasteners.

• Medical Devices – Ergonomic grips for surgical tools and adjusters.

Technical Specifications:

• Tolerances: ±0.005" (standard, tighter tolerances available)

• Surface Finish: Smooth knurled edges with optional deburring/polishing

• Compatibility: Can be combined with threading, milling, or turning

Why Choose This Knurled Part?

• Enhanced Usability – Prevents slipping in wet or oily conditions.

• Aesthetic Appeal – Adds a professional, machined look.

• CNC Precision – Consistent quality for high-volume production.

Custom sizes, materials, and knurling patterns available—contact us for your specific requirements!