2025-05-31 07:02:40

Stainless steel pins may seem tiny, but they represent a keystone in the structural integrity and working of innumerable products and machines stretching across various industries. From vehicles and electronics to heavy machinery and medical supplies, these small but robust fasteners find application in almost everything. With the advancement of digital platforms and the growing need for rapid procurement, many businesses and individuals are now searching for stainless steel pins on the Internet.However, with so many vendors on the Internet, how do you know which one to trust? This extensive guide takes you through what to look for, different types of stainless steel pins, their applications, and why PSHardware is a prime choice for stainless steel pins and stainless steel automatic parts.

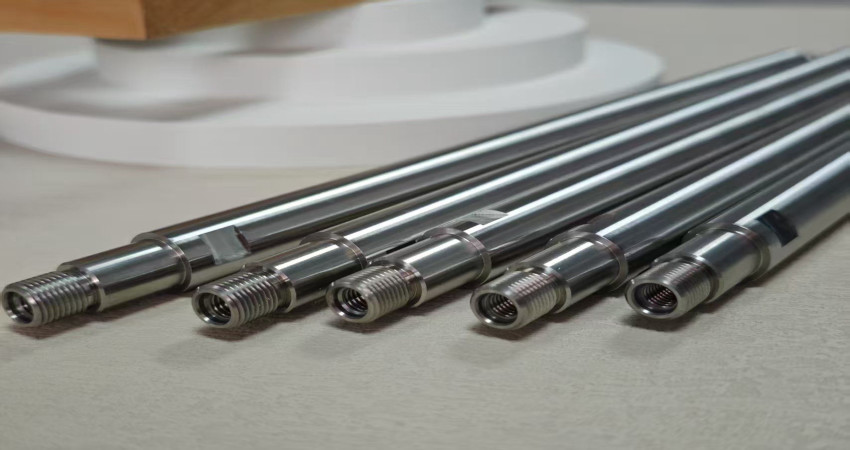

Strength, versatility, and reliability ultimately rank stainless steel pins above the rest. One outstanding reason for the widespread use of stainless steel pins is their exceptional resisting power to corrosion. Hence, these pins are suitable for use inenvironments that are subjected to moisture, chemicals, or outside conditions, while other metals can fail due to rust or degradation.Stainless steel is famous for its tensile strength. These pins tend to lessen high-pressure loads and mechanical stress on high-load or high-motion systems. Stainless steel pins provide reliability that engineers and designers count on in areas where precision and durability are paramount, like engines, turbines, or robotics. On the other hand, stainless steel being non-reactive makes them fit for industries like food processing, pharmaceuticals, and medical devices, wherein contamination must be avoided. These pins do not react when immersed in bodily fluids, chemicals, or food-grade materials, making them safe and compliant for sensitive applications.

Due to their ability to hold parts together while resisting wear over time, stainless steel pins play a key role in a variety of industrial and commercial applications. In the automobile sector, they align and hold components together in gearboxes, engines, and braking systems. Vibration and mechanical stress resistance make these pins a must in this industry.In construction, they are used for holding joints and fastening structural parts, thereby ensuring the safety, stability, and overall integrity of buildings, bridges, and machinery. Miniature stainless steel pins secure circuit boards in electronics and render electrical conduction possible in tight areas.Stainless steel automatic parts composed of custom-made pins are widely applied in automation systems, robots, and CNC machines to assure accurate and smooth functioning. From medical surgical tools to aerospace engineering, stainless steel pins aresilent enablers of innovation and safety.

If you are going to select the right component for your project, it is important that you know the types of stainless steel pins available online. We can focus on the widely used ones: 1. Dowel Pins Dowel pins are cylindrical rods inserted into corresponding holes to ensure machine components remain in proper alignment. This technique is often employed in mechanical engineering and assembly lines; there are tight tolerances and excellent load-bearing capacity introduced through dowel pins. Stainless steel dowel pins resist corrosion and wear in long-term applications. 2. Cotter Pins Cotter pins are intended to fasten bolts or other fasteners in place. Normally these split-type pins are located in machinery where parts need to be locked but can subsequently afford some movement or flexibility. Stainless steel cotter pins afford additional protection in very aggressive or corrosive conditions, minimizing the operational need for maintenance. 3. Taper Pins Taper pins are characterized as tapering one side toward their narrow end that is purposely made to fit firmly in place. Primary applications for taper pins are used for fastening parts that are to be assembled and disassembled on a regular basis. The shape ensures that the components remain tightly connected even under vibration or pressure. 4. Groove Pins Groove pins, also called slotted pins or serrated pins, are characterized by axial grooves along the length to increase gripping power and to avoid any degree of free rotation. These pins are extensively utilized in assemblies wherein torsional forces are experienced, so that parts remain locked in position. 5. Spring Pins (Roll Pins) This is a hollow cylindrical pin built from rolled stainless steel strip. It provides a fastening solution that is flexible and strong. When inserted into a hole, spring pins can compress and expand to come into place. Due to spring characteristics, it holds tension and resists loosening for a very long time. 6. Clevis Pins Clevis pins are co-joined with a cotter pin or retaining clip as a quick-release mechanism. Mostly used in mechanical linkage, clevis pins allow for quick assembly and disassembly which suit applications requiring frequent servicing. With a wide assortment of these types of pins, PSHardware guarantees that its customers will find exactly the needed stainless steel solution for their projects.

1. Grade of Material: All stainless steel is far from being created equal. The pins ought to be 304 or 316 stainless steel grade, which has excellent corrosion resistance as well as mechanical strength. The 316-grade pin is particularly suited to marine or chemical environment due to the presence of a large amount of molybdenum. 2. Tolerance and Dimensions: Precision becomes even more crucial for industries like aerospace or automotive. Make sure that the order pins match the exact specification and tolerances. Tighter tolerances mean better alignment and structural integrity. 3. Certification and Standards: Ensure the adherence to quality standards, including ISO, ASTM, etc. These certifications mean that the product has gone through rigorous testing and met quality benchmarks and gives you assurance in high-stake applications. 4. Quantity and Pricing: Find out if the supplier offers some flexibility in quantities and competitive pricing for bulk supply. Some online suppliers might even offer good discounts on larger orders, which will turn out to be immensely helpful for most manufacturers and assembly plants. 5. Fabrication Options: In some cases, you do not want one-size-fits-all solutions. Choose suppliers like PSHardware that offer custom manufacturing for pins tailored to your size, design, and application requirements. 6. Customer Service: Good after-sales support is another most important point while buying technical components. Check if the vendor provides prompt service, has an easy return policy, and offers trouble-shooting.

Among a few online hardware stores, PSHardware emerges ahead among most others due to quality, accuracy, and customer satisfaction. Arguably, their further catalog in online purchases remains a beneficiary since they spread in the dimension of stainless steel pins and automatic parts and concern themselves chiefly with industrial-grade solutions.

1. The Wide Range:PSHardware remains a one-stop place for all variants of stainless steel pins. Whether it is dowel pins for engineering purposes or clevis pins for mechanical linkages, stocks are directed toward the peculiar needs of both small workshops and large industries. They also carry an entire line of stainless steel automatic parts, so that the parts find purpose in automated systems and machines. 2. Top-Quality Materials: All stainless-steel pins from PSHardware are made from high-grade raw materials, including 304 and 316-grade stainless steel. This offers such characteristics as good resistance to corrosion, strength, and durability. The pins are designed for high-performance in severe environments and demanding industrial applications. 3. Customization Options: Whereas generic suppliers apply a one-size-fits-all approach, PSHardware understands that this does not always work. Their custom fabrication services allow clients to submit technical drawings or specifications, enabling the production of pins to tight tolerances, lengths, and features. Whether it is prototype runs with single pieces or truly large production batches, PSHardware delivers pure precision. 4. Competitive Pricing: An even pricing structure operates for all products, thanks to direct procurement and manufacturing within PSHardware. A professional working on a batch of 100 as much as on that of 10,000 will find that their value-for-money assurance operates for him on Standard Operating Procedures. 5. Fast Delivery and Logistics: One of the strengths of PSHardware is speed and reliability in delivery. Orders are efficiently processed, with dispatch of most in-stock products within the next 24 to 48 hours. They ship across India and offer global delivery, which is a huge plus for the international clients. 6. Certificates and Quality Assurance: Every product gets a rigorous quality check, following international standards. PSHardware provides certificates and documents of compliance on request, which is vital for industries that need compliance and traceability. 7. A User-Friendly Website:PSHardware's online shopping experience is intuitive, rapid, and secure. It is endowed with various sophisticated product searches, product datasheets, and simple checkout. Thus, it offers an uninterrupted buying experience. It has real-time chat support service and technical consultancy to support buyers in making their selection.

PSHardware caters for a wide range of industries through stainless steel pins and automatic parts. These products are used in: • Automotive Manufacturing: For engines, brake systems, and transmission parts. • Machinery and Robotics: In precision joints, axes, and alignment components. • Construction and Infrastructure: Used in structural assemblies and fastening solutions. • Medical and Healthcare: For surgical tools, implants, and diagnostic equipment. • Electronics and Electricals: In circuit boards, connectors, and housing frames. They stand out as a trusted partner for both OEMs and MRO operations due to their ability to provide customized and ready-made stainless steel automatic parts.

Ordering from PSHardware has always been simple and secure. Here is how you proceed: 1. Heading towards the official website: www.pshardware.com 2. Search for specific stainless steel pins using the search bar or browse through categories. 3. View product specifications, availability, and select your quantity. 4. Add to cart and proceed to checkout with secure payment options. 5. Receive order confirmation and tracking details for smooth delivery experience.

In today's industrial fast world, choosing the right supplier for stainless steel pins and steel automatic parts is not just a buying decision, it is a strategic one. You need a partner who gives you quality, reliability, and value for your money. With a comprehensive product catalog, commitment to excellence, and unparalleled customer service, PSHardware is worth it for those and more. Whether you are a small manufacturer, a big industrial firm, or a DIY artisan, PSHardware has the stainless steel solution that perfectly fits your need. Visit www.pshardware.com today to browse the complete range of stainless steel pins and automatic parts—and infuse your projects with precision and performance.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025