2026-01-15 10:53:26

The current manufacturing industry is highly precise in nature and necessitates high standards of accuracy, longevity and regularity of components. Automatic Turned Stainless Steel Part is one such part that can be seen to be practically applied in every industry. These components are manufactured with state of art automatic and CNC turning and provide a high degree of accuracy, smooth finishes and performance. In the automotive and aerospace industries, as well as in electronics or medical equipment, automatic turned stainless steel parts are currently crucial in the manufacturing industries.In this blog, we will described what automatic turned stainless steel parts are, what their characteristics are, how they are used, and what kind of benefits can be expected, as well as How To Buy Automatic Turned Stainless Steel Parts with one of the trusted suppliers.

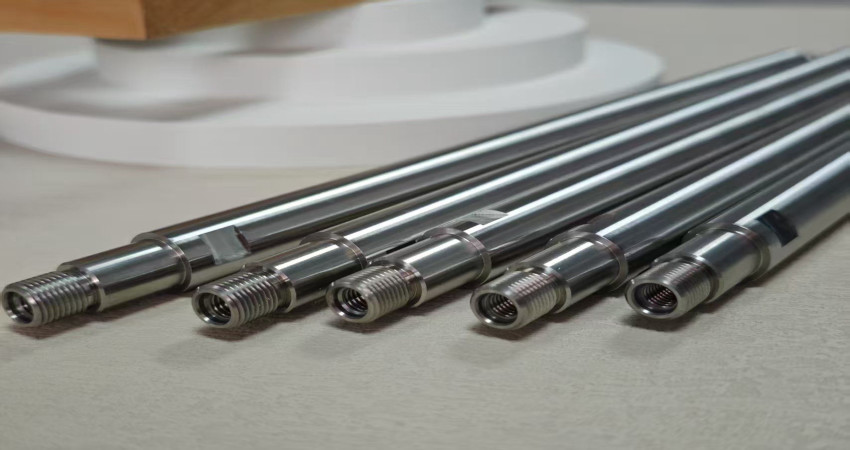

Automatic Turned Stainless Steel Part is a highly engineered part made on the automatic lathes or CNC turning machine. The machineries turn the stainless steel rods and are cut using the tools to give them the precise size. The process enables the production to be high-speed, exceptionally accurate and repeatable.Automatic turning is best suited to making complicated geometries, tight tolerances and high volumes of components. It minimally produces human error and guarantees uniform quality in each batch as compared to manual machining.

Some of the notable characteristics of automatic turned stainless steel parts are:

High Precision and Accuracy- The CNC and automatic turning machines are used to create components that have tight tolerances and hence suitable in critical processes where precision is vital.

Excellent Surface Finish- The turning is done, and smooth and uniform finishes are obtained, and further surface treatment may not be necessary.

Corrosion Resistance- Stainless steel is very resistant to corrosion, rust and oxidation and therefore such parts are the best in harsh environment.

Strength and Durability- Stainless steel parts have a high structural integrity against high stress, changes in temperature and mechanical loads.

Continuous Quality- Automated machining provides uniformity, even in high-volume production which is paramount to the industrial assembly lines.

These are highly applicable in various industries because they are versatile and reliable.

Automotive Industry- Used in engine components, fuel system components, sensors, shafts and fasteners in which durability and precision is the key factor.

Aerospace and Defense- Used in fittings, connectors, and structural parts which have high strength, corrosion resistance, and precision.

Medical and Healthcare Equipment- Will be used in surgical instrument use, implants, and medical equipment where the hygiene, accuracy, and quality of materials are crucial.

Electronics and Electrical Industry- This is typically applied in connectors, pins, terminals and housings that may need precision and conductivity compatibility.

Industrial Machinery- These are found in valves, couplings, bushings and mechanical assemblies that have constant loading.

Affirmative Quality Mass Production- Automatic turning is a cost-effective way to produce in large quantities, faster production cycles, which allow the unit cost to be lower.

Less Material Waste- Precision machining is the least amount of scrap and material is wasted.Customization and Flexibility- The Custom Stainless Steel Parts Online can be easily manufactured based on the drawings, samples or technical specifications by the manufacturers.Reduced Lead Times- Automation guarantees reduction in turnaround time thus assisting the business to complete deadlines.

Long Service Life- Stainless steel of high quality that is used with high precision machining ensures low maintenance and durability.

CNC Turned Stainless Steel Comp represent the elements that are produced with the help of the Computer Numerical Control system. CNC turning enables the manufacturers to program more complicated designs, which is consistent and repeatable.When you are in need of Where to Buy CNC Stainless Steel Turning parts, you should select a supplier that has the current CNC facilities, qualified technicians as well as strict quality control measures. CNC turning is suitable in prototypes as well as in high volume production.

How and where To Buy Automatic Turned Stainless Steel Parts: the factors to be considered include the following:

• Check material grades and certifications.

• Assure good tolerance.

• Inquire of customization.

• Check quality inspection and testing.

• Check production capacity and delivery schedules.

Most manufacturers are providing online ordering systems so that it is easy to source Custom Stainless Steel Parts Online with full technical support.

A Local or regional supplier is also likely to find a quicker method of communication, a shorter shipping period, and more cooperative in the search results when searching on Automatic Stainless Steel Machining Near me. An effective machining supplier must offer:

• High-level CNC and automated turning equipment.

• Talented engineering and production departments.

• Specialty-troped prototyping and large scale production.

• Quality assurance.

The local machining partners are also quite advantageous when the company needs the frequent design changes or needs the production schedule very short.

Automatic turned stainless steel components of high quality are produced under the rigid quality requirements. Qualified suppliers abide in ISO regulations, they do dimensional verification, and they carry out material checks to verify that every part is up to the requirement of the customers.Such quality control is necessary in those industries that do not have the option of failure of components.

Modern precision manufacturing is based on automatic turned stainless steel parts. They are high in accuracy, strength, corrosion resistance and flexibility, thus they are applicable in a broad spectrum of industrial uses. Regardless of whether you require standard parts or complete Full Custom Stainless Steel Parts Online, it is important to ensure that you select the correct manufacturing partner so that you can be assured of quality and performance.When you need professional solutions to Automatic Turned Stainless Steel Parts manufacturing, advice on How To Buy Automatic Turned Stainless Steel Parts, or advice on solid sources of Where to Buy CNC Stainless Steel Turning parts, a knowledgeable supplier is all you need.To any business that requires accuracy, dependability, and high-tech Automatic Stainless Steel Machining Near me,pshardware.com is a reliable company that produces high-quality CNC and automatic turned stainless steel parts that suit the needs of various industries.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025