2025-05-22 12:04:55

By rapid prototyping, we mean the speed on which new products get into the manufacturing system. All pros are giving prototyping credits to this fast manufacturing, be it automotive or aerospace industries, mostly using the aluminum CNC machining to replace functional prototypes with the end-product performance that they need to achieve. It is the turnaround and quality of this prototype that would ensure a successful product launch.All of these manufacturers exist globally, and the hardest and most critical decision concerns choosing the right one. PSHardware, a trusted name among CNC machining titans, has been in the business for a long time and known to deliver models using high-quality aluminium CNC machining prototypes. This blog takes a closer look at the reasons for considering aluminium as the best material for CNC prototypes, the characteristics that make a supplier trustworthy, and how PSHardware stands out.

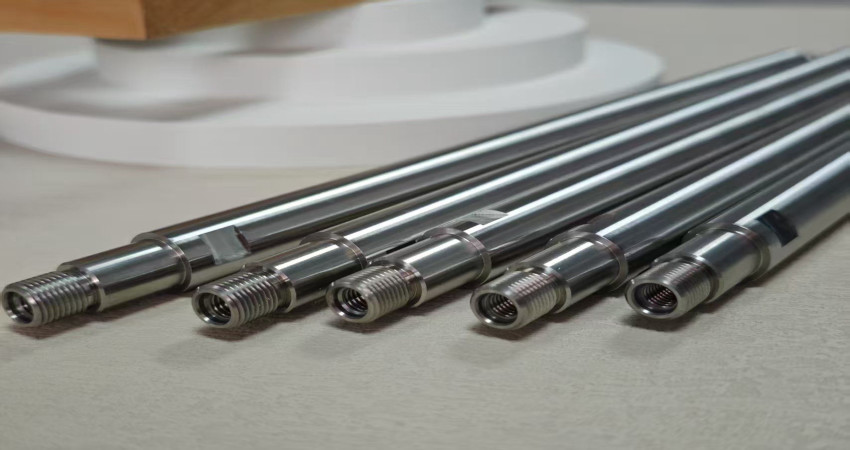

Aluminium, indeed, counts as probably one of the most widely used materials for CNC machining. All desirable properties are found among the material, which renders it suitable for prototyping speed, precision, and versatility. 1. Good Machinability Saves Time and Reduces Accumulating Costs Aluminium is apparent for easy and leisurely machinability and CNC machines, may easily and promptly cut and shape this material into shape. Unlike harder metals that wear down tools and slow down production, aluminium offers smoother processing with minimal resistance. This not only speeds prototype production but also significantly reduces tool maintenance and energy costs. The time and cost savings for manufacturers are tremendous in that time during product development. PSHardware uses CNC equipment that efficiently optimizes these efficiencies with the properties of aluminium to promote rapid turnaround yet high precision.

2. Light but Strong Enough to Use Structural Functional Testing Aluminum is a great compromise between its weight and strength. This makes it very suitable for prototype parts that must be both strong and lightweight. Engineers working in the aerospace or automotive fields would like materials that can imitate final product conditions and are light enough to prove the point. Aluminum prototypes are strong enough to undergo mechanical testing and yet keep themselves intact and in shape. PSHardware produces lightweight, structurally sound aluminium prototypes that can be directly used for real-world testing without any compromise in performance.

3. Natural Corrosion Resistance for Longer Endurance in Environment One of aluminium's exceptional characteristics is that it resists corrosion. Its experimentation with air makes a protective oxide coating which keeps it free from rusting or degrading processes. In this way, aluminum CNC prototypes can be well deployed in outdoor and highly moist places where it is crucial to durability. PSHardware uses precision finishing and optional anodizing treatments to complement this natural resistance, so that your prototypes can go through long developmental cycles and have been exposed to environmental simulations.

4. Superior Thermal and Electrical Conductivity for Specialized Applications Heat sinks, enclosures, and electrical connector components are therefore highly sought after. PSHardware engineers understand just how to optimize aluminium's conductive properties within their CNC machining process, delivering prototypes that perform as close to the final product as possible—especially when thermal efficiency is a key design factor.

Finding the right supplier for aluminium CNC machining prototypes is not just a matter of research on price comparison. A number of very essential qualities distinguish mediocre suppliers from the real industry giants like PSHardware.

1. Advanced CNC Technology and Tooling Capabilities A good supplier should be fitted with modern CNC machines, which would be able to give tight tolerances with high repeatability. PSHardware heavily invests in multi-axis CNC milling and turning machines, gaining exceptional dimensional control and flexibility. They have all facilities through which simple and complex geometries can be handled consistently.

2. Competent Engineers and Experienced Machinists The quality of the final prototype is greatly dependent on the skills of the people working behind the machines' operations. PSHardware boasts an experienced team of engineers and CNC specialists who've been around in working with aluminium for most of their professional lives. They know material behavior, tool paths and design optimization- guaranteeing perfect engineering for every prototype.

3. Material Certification and Quality Control Systems The top suppliers give a certificate of authenticity for aluminium making; they will also put a strict quality control standard in place along the production cycle: PSHardware does everything under ISO compliance and multi-step inspections done on every prototype, from raw material verification to final dimensional analysis. This procession makes sure you get a perfect final product.

4. Scalability and Customization Scaling capacity is crucial whether you need a single prototype or a low-volume production run. PSHardware scales up alongside CNC machining services and provides customization options such as surface finishing, anodizing, sandblasting, and more. This gives your client an easy way to tailor prototypes according to functional or aesthetic goals.

5. Speedy Turnaround Times Combined with Reliable Delivery Rapid prototyping meant speed without sacrificing quality. With optimized production workflows and backed by dedicated logistics support, PSHardware is now among the fastest lead times in the industry. This enables clients to have reliable delivery schedules even for complicated, customized projects involving aluminium CNC machining.

After discussing what makes a great CNC machining partner, now let's dive into the features that make PSHardware the best option when buying aluminium CNC machining prototypes. 1. Industry Leading Expertise with Decades of Experience With years of CNC machining experience and a tremendous reputation for providing premium-quality aluminium prototypes across a broad range of industries-from automotive to consumer electronics-almost everything these days has matured to be expected with deep industry insight and anticipatory client needs, such as in solutions by fabrication. 2. Fully Integrated End-to-End Services End-to-end includes everything from CAD design support, through selecting materials, machining, surface finishing, and shipping. This one-stop-shop mentality reduces the need to deal with so many vendors, smoothes communication, and ultimately saves development time. 3. Innovation in Customer-Centric Commitment This PSHardware team believes in building a long-term business relationship through innovation and customer satisfaction. Their engineers collaborate with clients to tweak designs to improve manufacturability, ensuring prototypes meet performance and aesthetic criteria. You get more than a part-you get a partner with a vested interest in your success. 4. High Precision for Complex Parts and Tight Tolerances Need intricate internal features or specs that require tight tolerances? PSHardware specializes in high-precision machining of complex aluminum parts requiring very high accuracy. With high-tech equipment featuring 3-, 4-, and 5-axis machining capabilities, they can produce even the most challenging designs without compromising quality. 5. Affordability with Global Reach While PSHardware affirms that quality and speed are mandatory requirements for any project, the company understood that affordability is still necessary. All prices are competitive, supplemented with value-added solutions that will help the client stay within budget but not in performance. With an international clientele in its portfolio, PSHardware is capable of delivering prototypes anywhere in the world through unparalleled logistics partners.

Getting started with PSHardware is easy and transparent if you're ready to enjoy top-tier aluminum CNC machining services. 1. Upload your CAD files or drawings: Begin by sending your 2D or 3D CAD files to PSHardware's technical team. They accept numerous formats and are equipped to review complex geometries. 2. Get a free quotation that includes lead-time estimates: After reviewing your files, you will be given a detailed quotation that will include price, lead time, and any value-added options such as surface finishing or post-processing that may apply. 3. Collaboration with the Engineering team: If your project needs design optimization or feedback, engineers from PSHardware are delighted to provide expert suggestions that would enhance the performance of the part or minimize manufacturing costs. 4. Production and Delivery: With confirmation that everything is as it should be, your prototype moves into production using cutting-edge CNC equipment. PSHardware keeps you Get Started with PSHardware: Fast, Simple, and Transparent Process

1. Upload your CAD files or drawings: Begin by sending your 2D or 3D CAD files to PSHardware's technical team. They accept numerous formats and are equipped to review complex geometries. 2. Get a free quotation that includes lead-time estimates: After reviewing your files, you will be given a detailed quotation that will include price, lead time, and any value-added options such as surface finishing or post-processing that may apply. 3. Collaboration with the Engineering team: If your project needs design optimization or feedback, engineers from PSHardware are delighted to provide expert suggestions that would enhance the performance of the part or minimize manufacturing costs. 4. Production and Delivery: With confirmation that everything is as it should be, your prototype moves into production using cutting-edge CNC equipment. PSHardware keeps you

In aluminum, plastics, or other materials, quality, precision, and reliability are the factors that decide the success of trying to acquire that aluminum CNC machining prototype. These decisions start with proper specification of electroformed mold-making characteristics in aluminum to the decision of choosing a reliable and trustworthy supplier. PSHardware stands among the very best as a global leader in CNC machining, offering cutting-edge quality and quick turnaround for any expert support and customer satisfaction as well. Whether you are an innovator pouring in time and resources to bring a new product to market or a manufacturer in search of precision-engineered components, PSHardware is your ideal partner for coming up with aluminum CNC machining prototypes. Request a free quote from PSHardware today to take the first step toward making your design a reality and enjoying its eventual success in the real world.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025