2025-05-16 09:37:35

There is almost precision in any mechanical arrangement, while the machine itself gets the real efficiency from its primary components. It is in the turning components that come from CNC machining tooling steel; they are the critical mass because these parts possess excellent mechanical properties and are great at withstanding stress and wear. Understanding how to go about ordering tooling steel CNC turning components for your existing systems or the new machinery you are designing, or even for your involvement in large-scale production, can significantly improve your processes.This is a well-detailed guide covering everything you need to know - from the basics of tooling steel and CNC turning to aspects to take into account with regard to placing orders and selecting the best possible suppliers.

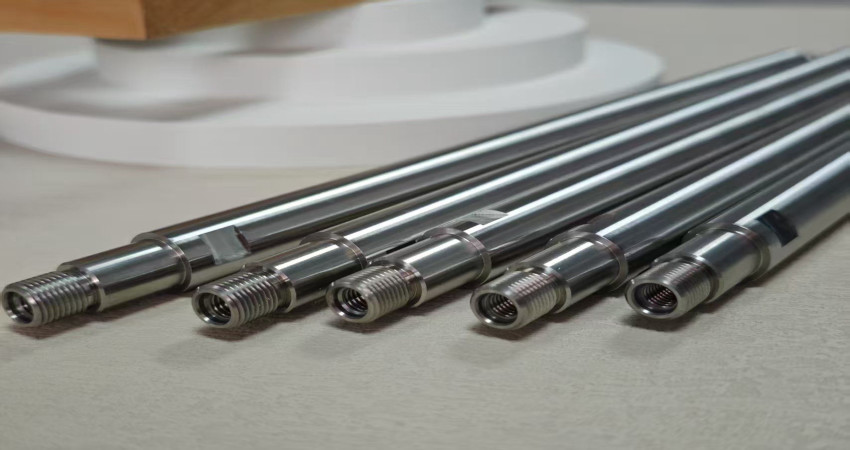

CNC (Computer Numerical Control) turning is the process of shaping an object by inserting a cutting tool into the object, which is then rotated, instead of making a mold into a rotating tool. It is one of the most used techniques in manufacturing for the crafting of cylindrical parts with very high accuracy and good surface finish. Tooling steel is considered one of the heavyweight champions and is the most widely used material for CNC turning components with its level of durability, heat resistance, and wear tolerance.Tooling steel is a type of carbon and alloy steel designed specifically for the manufacture of tools. It's used for making cutting tools, dies, and punches and other components that experience a repetitive motion and force. The main types of tooling steel are cold-work tool steel, hot-work tool steel, and high-speed steel (HSS), the selection of which depends on the temperature and load conditions for which the application is intended.

Tooling steel is an excellent candidate for high-demand machining operations. The parts thus made up of CNC turned systems turn out to be no less than just precisely made but also sturdily strong.

1. Better Hardness and Wear Resistance: Tooling steels such as D2, H13, A2 and M2 possess high Rockwell hardness ratings that would not deform even under extreme load; this is essential for use in vehicle gear assemblies, dies, and molds.

2. Thermal Stability and Heat Resistance: Hot-working tool steels such as H13 perform really well at higher temperatures and are therefore ideal for CNC-turned components used in high-temperature applications such as plastic molding, die casting, and aerospace engine parts.

3. Dimensional Stability and Accuracy: CNC turning with tooling steel minimizes distortion and possesses excellent dimensional stability, as it is necessary for parts that hold tight tolerances throughout their life cycle.

4. Corrosion and Compromise Resistance: Most grades offer fatigue and corrosion resistance and are treated to enable the finished components to withstand the rigors of the industrial environment, chemicals, and mechanical wearing.

Tooling steel is selected according to the application specific to its purpose and machining environment. These are the most common examples of tooling steel used in CNC turning:

• D2 Tool Steel - High Carbon, High Chromium Best used in cold working, D2 has excellent hardness and abrasion resistance. Designed for forming dies, gauges, and precision tools.

• H13 Tool Steel - One of the Hot Work Steels Its resistance to thermal fatigue cracking makes H13 suitable for a wide array of applications in die casting, tooling for extrusion, and forging dies. Proper for use in CNC turning parts that also experience high temperature.

• A2 Tool Steel – Air-Hardening It has good balance between toughness and wear resistance. A2 is an excellent choice for fixtures, dies, and punches.

• M2 High-Speed Steel - Excellent Cutting Performance This is commonly used in cutting tools, drill bits, and industrial blades. Retains its hardness even at high temperatures, making it an ideal candidate for turning complex parts at high speeds.

Ordering CNC-turned tooling steel components involves more than just selecting the right material. A few factors to be considered then include:

1. Define Accurate Purpose of Application This can be through the following points that should be considered before ordering:

• Load Conditions: Static or Dynamic

• Operating Temperature

• Chemical or Moisture Exposure

• Precision Tolerances

• Finish and Coatings Requirements

2. Tooling Steel Grade Selection: Choose the right tooling material grade based on your application's need, like H13 for high-heat applications, D2 for heavier wearing operations, and A2 for balanced toughness.

3. Give Detailed Technical Drawings: Suppliers require full CAD drawings or 3D models with dimensions, tolerances, and machining instructions. With accurate documentation, production errors and reworks can be significantly lowered.

4. Specify Surface Treatments or Coatings: According to the end use, your components may need one of these treatments: nitriding, carburizing, black-oxide coating, or some other, to ensure corrosion resistance or hardness.

5. Verify Supplier's Capabilities: Not all the manufacturers have the tooling to machine certain grades of tooling steel. Make sure that the chosen supplier has advanced CNC lathes, mills, and grinding machines, and can handle heat-treated or hardened materials.

Your CNC-industrially turned tooling steel components' quality is going to be determined primarily from the manufacturer's capabilities and reputation. Here is why it is important to choose a reputed supplier:

• Source for High-Quality Materials: Certified suppliers ensure that the tooling steel conforms to international standards such as AISI, DIN, or ASTM, thereby providing consistency and performance.

• Precision Engineering with Advanced Machining Tools: Top players have employed 5-axis CNC machines, Swiss-type lathes, and live tooling, which result in most accurate and complex components.

• Quality Assurance and Testing: Proper CMM interpretation, ultrasonic inspection hardness verification, among other checks, offered by leading suppliers, will ensure defect-free deliveries.

• On-Time Delivery and Support: Professional vendors abide by deadlines and also offer constant support from initial design consultation to post-production service.

When outsourcing tooling steel CNC turning services, ensure that the vendor can provide the following:

• Tolerance Capabilities: Tolerance to ±0.005 mm

• Scalability: from small-scale quantity prototyping to production of many

• Secondary Operations: Such as heat treatment, coating, deburring, or laser engraving done under one roof

• Material Certifications: Material grade, heat number, and testing results documentations

• Worldwide Delivery Service and Custom Clearance Assistance (if importing)

CNC-turned tooling steel components find application across several sectors, thanks to their superior performance and durability.

• Automotive Industry: Tooling steel components are used in gears, shafts, and transmission parts that ensure high performance under pressure and motion.

• Aerospace and Defense: Safety and reliability for critical applications are assured through CNC turning with high-strength steel where accuracy is paramount to aerospace.

• Mold and Die Manufacturing: Mold inserts, core pins, and die holders require hard-wearing steel. Tooling steel CNC components offer excellent lifecycle value.

• Heavy Machinery and Industrial Equipment: Hydraulic cylinders, bearing housings, and couplings benefit from the durability of tooling steel.

• Medical Equipment Manufacturing: These precision CNC components made from clean and corrosion-resistant steel grades are crucial for surgical tools and diagnostic equipment.

Although tooling steels are relatively expensive and CNC machining is also expensive, one can cut costs without sacrificing quality in the following ways:

• Order by Batch: Generally, larger volumes reduce prices;

• Standardize Components: Use standardized components whenever possible to avoid custom tooling;

• Collaborate Early with Suppliers: Design for manufacture (DFM) reviews will usually discover opportunities to save costs.

• Request Multiple Quotes: Have several vendors quote but ensure that the basis for comparison is identical across vendors.

• Local Suppliers: Reduces shipping costs and possible delays for urgent orders.

The CNC machining landscape continues its rapid evolution through automation, AI, and data analytics. In the coming years, we can expect:

• Normalized smart CNC machines changing the speed and path of the cutting tools based on real-time data.

• Predictive Maintenance causing less downtime and better output in all components.

• More Use of Simulation Software for toolpath verification before work commences.

• Machining Practices made sustainable, with better coolant recycling and waste reduction. Being abreast of such happenings will put you in a good position to future-proof your machining strategies and optimize your investments.

CNC turning components using tooling steel are not merely procurement decisions; they are investments in quality, productivity, and longevity of machines. The careful selection of the right material grades, with precise machining, guarantees that equipment runs at an optimum level. When needing to render orders, always utilize credible suppliers who will provide not only machining but engineering support as well as quality assurance. Careful planning alongside clear specifications and collaboration will tap the full potential of CNC-turned tooling steel parts in an operation.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025