2025-04-21 12:53:31

To boost speed in an era of rapidly changing industries and to keep factories simple and error-proof, automation is, mainly, a pivot or a central axis around which the others revolve. Stainless-steel pins form the very core of highly automated systems. These pins may seem insignificant compared to other larger components, but they perform an important function in mechanical efficiency and reliability in the operational performance of numerous automated assembly applications.Stainless steel pins are replaced with mechanical alignment, movement and fastening, and structural support by means of robotic arms, CNC machines, conveyor systems and high-speed assembly line. It is vital to choose the right ones for applications like these, and that's where PSHardware, a manufacturer of precision fasteners and components, will Endows its value.

Automation systems require very high precision with very strong durability to withstand long-term operations under repetitive load and variable conditions of use. Stainless steel pins typically perform excellently under these conditions. Here are some reasons why:

• Corrosive Resistance: Stainless steel is well known for its anti-corrosive quality when subjected to moisture, chemicals, or temperature fluctuations. Thus, ensuring that pins last even in demanding working conditions such as marine, chemical, or food processing industries.

• High Mechanical Strength: Stainless steel pins are capable of resisting very large tensile or shear forces without yielding. This makes them suitable for load-bearing applications inside automated assemblies where reliability and stability may be non-negotiable conditions.

• Resistance against wear and Durability: With its great toughness, stainless steel withstands repeated cycles of operation without any noticeable wearing. Therefore, machines stay longer and are serviced less.

• Precision and Repetition: This type of steel is capable of producing very fine machining which is very important if pins are to be used for positioning, alignment, or guiding. Consequently, this will result in precise, repeatable performance in automatics where even very slight differences can lead to operational failure.

• Hygienic and Easily Cleaned: In terms of preference, stainless steel would be preferred because its clean surface and non-reactive nature is best in circumstances such as food processing and manufacturing medical equipment.

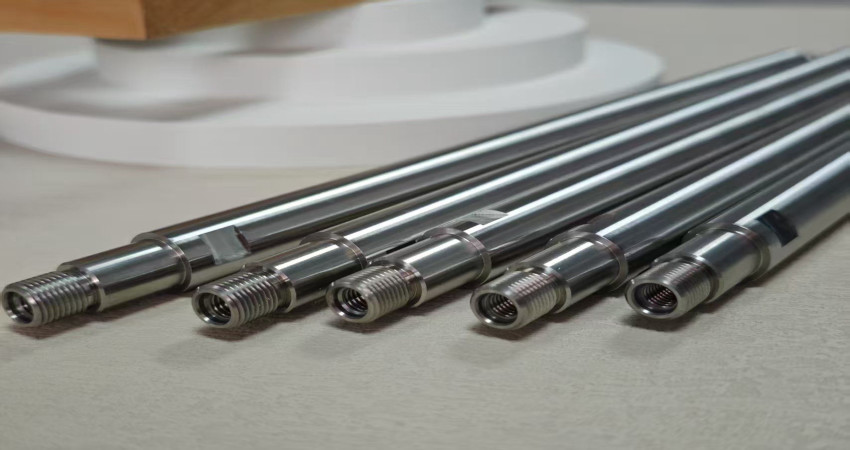

There are different categories of stainless steel pins, each of them designed to perform mechanical or structural functions. Knowing their types will help in choosing the right pin for automated machinery.

• Dowel Pins: They're solid cylindrical pins used for very precise alignment between two components. In automation systems dowel pins are used for keeping parts in the exact positions relative to one another during high-speed motion or vibration. Hardened and ground dowel pins in various tolerance levels are offered from PSHardware to address these stringent industrial standards.

• Clevis Pins: These pins have a head on one end and holes upon the other. Clevis pins are along with a retaining clip or cotter pin attached to it. They serve as a pivot or hinge component and thus are used in actuating and mechanical linkages in automated machines.

• Spring Pins (Slotted Pins): These pins are hollow with longitudinal slots so that they can compress when installed. They can then regain their original diameter for a tight grip inside the housing. They're perfect for places where shock absorption and strong yet vibration-resistant fastening are required.

• Groove Pins and Taper Pins: Groove pins have grooves or knurls that grip the surrounding material, while taper pins are slightly conical and wedge into mating holes to secure assemblies. These pins are used in rotating components and gear-driven systems where axial forces are present. Each one of them is employed for a distinct purpose and picking the most appropriate one is tough as it depends on the machine operation, involved forces and conditions where the pin will work.

So choosing the right stainless steel pin is not all about selecting a shape or size. There are critical parameters that need to be verified for optimal performance and fitment with the automation systems: • Material Grade: Not all stainless steels are the same. For example: o 304 Stainless Steel is an economical stainless steel with an all-purpose level of corrosion resistance. o 316 Stainless Steel encompasses molybdenum that provides exceptional corrosion resistance to chlorides and severe chemicals; a good choice for marine and medical environments. o 17-4 PH Stainless Steel is precipitation hardened and has a good mix of properties: excellent strength, corrosion resistance, and hardness, making it suitable for applications like aerospace and other high-stress environments.

• Tolerance Levels: Automation relies heavily on precision. Tight tolerance pins eliminate play and movement, allowing for precise positioning with minimal deviation. PSHardware offers pins with tolerance levels as low as ±0.001 mm.

• Surface Finish: A very smooth surface gives low coefficients; low wear and corrosion and polished or passivated stainless-steel pins further reduce galling risk among high-speed assemblies.

• Heat Treatment: Heat treatment is done to increase hardness and resistance to fatigue on some stainless steel pins. Depending on the operation, either hardened pins or those made of softer materials might be better suited to impact loads or wherein heavy loads are being applied.

• Load and Stress Requirements: Knowledge of the axial and shear forces acting on the pin will help determine the right diametrical size as well as length and material grade. If high impact areas enter the equation, then the pins applied in those areas will need high resistance to bending or breakage.

• Environmental Conditions: The material chosen generally corresponds to extreme temperature ranges, exposure to chemicals, or moisture. For example, food-grade environments necessitate stainless steel of grade 316 for hygiene and compliance reasons.

PSHardware is indeed making the best-known supplier and manufacturer of stainless pins, based on efficiency engineering, excellent quality control, and a customer-centric approach. • More than two decades of experience: PSHardware emphasizes the subtle demands of different industries such as automation, robotics, automotive, and medical technology with more than 20 years of know-how.

• Product Range: PSHardware has a large collection of stainless steel pins such as: o Precision ground dowel pins; o Spiral and slotted pins; o Taper pins; o Custom-milled specialty pins for proprietary automation designs.

• Best Raw Materials: The company sources only certified high-grade stainless steel materials as inputs for manufacture, thereby ensuring their products' strength, durability, and freedom from corrosion.

• Customization and Design Engineering Support: Technical staff at PSHardware work closely with clients to craft solutions to unique pin requirements. Be it a non-standard length, intricate geometry, or special coatings, PSHardware delivers on specifications and performance.

• Modern Manufacturing Capabilities: PSHardware integrates world-class CNC machining centers, robotic technological inspection, and automated packing with which all its pins meet international standards like ISO, DIN, ANSI, and ASTM.

• Quality is stringent at PSHardware: Every pin is dimensionally verified, hardness-tested, and assessed for corrosion resistance and the truthfulness of ISO 9001:2015.

PSHardware’s stainless steel pins are found to be used in many automation systems where precise and reliable applications are required. Application sectors are listed below: • Robotic Assemblies: Joint accuracy and load-bearing capacity for robotic arms and manipulators are dependent upon high-strength taper and groove pins. • Medical Applications: In surgical robots, diagnostic machines, and lab automation equipment, corrosion-resistant and sterile-grade pins ensure clean and consistent operations. • Automated Conveyor Systems: Clevis and dowel pins hold motion alignment and fasten mechanical parts across repeated load cycles within conveyor systems. • Electronics Manufacturing: Precision machined dowel pins are part of the fixture used in aligning during PCB assembly and micro-component placement in automated electronics production lines. • Food Circuit: Some clovin-clevis dowel pins-an example are the 316 ss grade ones from PSHardware that can be used in a food contact machine where cleanliness and hygiene, along with corrosion resistance, are essentials.

A world-renowned manufacturer of warehouse automation systems was suffering a problem of premature pin corrosion in their material handling robots. Existing supplier pins didn't survive against an environment of high humidity mixed with chemicals, which resulted into rising downtime and repair costs.

PSHardware's Approach: • Working conditions and material compatibility were analyzed.

• The recommendation was made for custom 17-4 PH stainless steel dowel pins with an electropolished finish to increase resistance to corrosion.

• Delivery of sample batch within a week for pilot testing.

• Modification of design with tighter tolerances for better fitting and stability. Results:

• Life of the pin increased over 300 per cent.

• Decrease on maintenance intervals.

• Client standardized PSHardware pins for all future production runs.

Sustainability and Innovation Followed by PSHardware In today's manufacturing world, sustainability is no longer optional but has to be applied. PSHardware abides by this philosophy and is working towards developing a minimal possible environmental impact while ensuring product excellence.

• Production: Eco-efficient: the company runs energy-efficient CNC machines, and includes waste metals generated during production in its recycling.

• Smart Manufacturing: It embraces Industry 4.0 principles with its data-driven quality control, IoT-integrated machinery for predictive maintenance, and process optimization.

• Customers' Guide: Best of all is to help customers and customers into making informed choices to help reduce unnecessary waste and rework is the technical blogs, detailed material data sheets, and best practices shared by PSHardware.

These steps will guide your selection of the right pin to optimize your automation needs:

1. Identify Application Requirements: Understand what the function of the pin will be in your system: alignment, fastening, movement, or load bearing.

2. Determine Operating Conditions: Environment, temperature, chemicals, and mechanical stresses are all things that might affect the pin.

3. Choose the Correct Material and Type: Use either the PSHardwarecatalog or speak directly to their experts regarding which grade and type of pin would be better for your application.

4. Order Samples and Prototypes: Do not move to bulk orders before testing sample batches under actual operating conditions.

5. Make a customized or standard order: PSHardware can fulfil all necessary global shipping and streamlined logistics to fit quickly into your supply chain.

Within a system of automation, stainless steel pins may be small items, but their use and purpose in an automated machinery system cannot be exaggerated-from alignment and fastening through structural integrity to motion control-these pins form the backbone of thousands of automated systems. When it comes to precision stainless steel pins with high performance, PSHardware becomes your trusted partner. Through its proficiency, strong stand on materials quality, and customer-centric solutions, it significantly stands out among suppliers in a very competitive market.Whether you're developing advanced robotics, medical automation, or industrial machines, PSHardware ensures your pins perform flawlessly—every single time.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025