2025-05-31 07:19:00

Modern-day industrial manufacturing has a substantial emphasis on carbon steel stamping parts, now widely regarded as the building blocks of an unfathomable number of mechanical and structural applications. These parts are strong, durable, and versatile so used across all industries: automotive, construction, electronics, and consumer appliances.All longevity and functionality of the components depend on the surface treatment done. White paint surface treatment is the best and most attractive one among them. pshardware specializes in manufacturing high-quality carbon steel stamping parts with expert white painting finishes which serve a dual function of protection and aesthetics value.

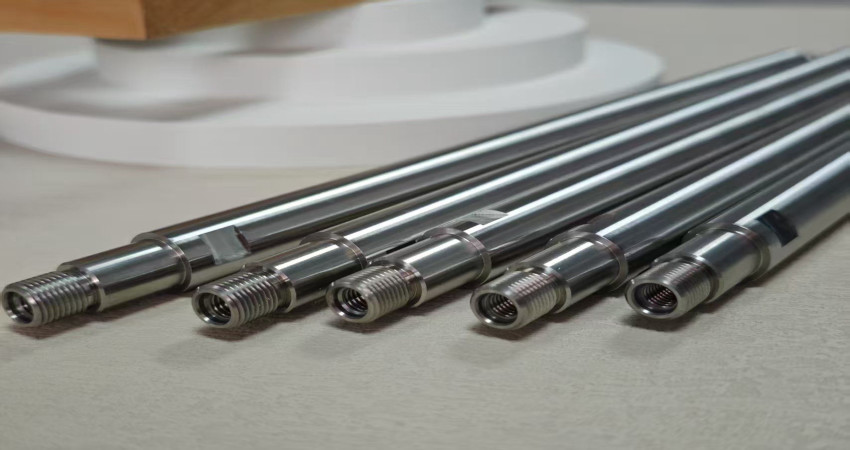

Combining carbon steel sheets into a specific shape through stamping using special dies-and-presses process brings forth carbon steel stamping parts, which can be assembled to create simple washers or formed into sometimes complex brackets and frames. Parts are capable of reaching from very simple to quite complex designs.Carbon steel works best of all stamp materials for its great tensile strength, low cost, and easy fabrication. This material does not compromise strength while offering malleability for an intricate design when making components such as those by pshardware.

There are various important reasons for the preference of carbon steel in stamping operations, of which below are some. The main reason that carbon steel is widely used is the excellent mechanical strength needed for parts that can withstand all types of pressure, vibration, or heavy loads. The application for carbon steel parts is structural and mechanical in nature. It is also the base of superior formability. Cuts, bends, punches - and all the operations take no effort to form parts into almost any shape;thereby, it minimizes the time & cost of production. Add to that, carbon steel is abundantly found and recyclable, which forms the basis of it being so much cost-efficient and eco-ethical. At PSP Hardware, we deal with the highest grades of carbon steels in line with global manufacturing standards, an assurance each stamped component is strong, uniform, and fit for purpose.

Carbon steel stamping parts find application in many sectors, as they provide tensile strength, flexibility in application use, and reduction in cost. Engine components, brackets, reinforcements, and chassis comprise the use of such parts in automobiles, because these components can withstand road vibration and heat from the engine. For construction, stamped carbon parts have applications in structural framing, anchors, and all types of support. It is fundamental to ensure the reliability and load-bearing capacity of buildings and infrastructure, wholesomely contributing to their overall safety and stability. Similarly, stamped parts are used in consumer electronics and appliances. Basically, whether internal skeletons of microwave ovens, or mounting brackets of air conditioners, its stamped parts made of carbon steel directly contribute to their functionalities and durability. All these custom-engineered stamped components, applying to various sectors, have been offered by pshardware, tailored for specific design and performance requirements.

The metal is indeed strong and hard-hitting, as well as cheap; however, it rusts when it comes in contact with moisture and air. The application of surface treatments aims towards enhanced corrosion resistance and life extension for such components. Apart from that, surface treatments improve aesthetics and enable functions such as UV resistance, electrical insulation, and easier cleaning. The most efficient and glozy methods of surface treatment are white painting, and this is what pshardware has been doing well over the years.

The surface treatment of white painting is the application of a specialized coating with white paint to the stamping parts of carbon steel. This coating protects the metal against corrosion while beautifying it such that it can be used in limited visible or consumer-facing applications. Usually, surface treatment is done through spray or powder-coating methods and then curing inside an oven to enhance durability and adherence. White paint can vary depending on gloss level from matte up to high gloss depending on the client's aesthetic needs. At pshardware, we utilize high-quality low-VOC (volatile organic compounds) paints environmentally friendly and reputable for durability.

Major Benefits of White Painting on Carbon Steel Parts

The major benefit to white painting is that its excellent corrosion resistance property. The paint will create a protective coat which prevents water, air, and all other corrosive agents from reaching unto the carbon steel underneath, and hence prolong the life of the component especially upon areas exposed to atmosphere with high humidity or moisture condition. White painting also enhances the aesthetic quality of stamped components. The modern, clean appearance of white-painted parts makes them well-suited for applications where appearance matters, such as in home appliances, office equipment, and furniture. The surfaces painted white are also better washed and maintained. Dirt and grease are visible on the whole and can be wiped off so that it remains unharmed by the paint. Therefore, treatment could be done under hygienic environments such as kitchens, medical equipment, and laboratories. Moreover, white-painted parts also bring little UV protection that helps preserve color and integrity when used outdoors or in other areas near windows. This will prove beneficial for construction and architectural applications.

Production of carbon steel stamping parts is just scratching the surface with what pshardware provides: It provides engineered solutions with the highest quality and functional performance. Our manufacturing embraces precision, innovation, and customer-centered design throughout.Advanced Equipment and Methods: Stamping is accomplished with tight tolerances and intricate designs using the advances in technology: CNC-controlled machines and automated presses. In stark contrast, our painting line uses modern spray and powder coating booths that guarantee unblemished coating with lasting finishes.Customization and Design Support: Every project is distinct; hence, our team of experienced engineers closely collaborates with clients to ascertain their needs and provide adequately tailored options. Every aspect of the part-design, material, and finishing-is supposed to be tuned for optimal performance and cost efficiency-from prototype through full production.Quality Assurance at Every Step: The quality control team inspects every component at various stages-the testing of incoming raw materials, in-process quality checks, and final inspection after painting. This method of multi-layered quality control guarantees that every single product leaves the unit having met all requisite quality standards.

One of our major projects was the supply of white-painted carbon steel brackets to that HVAC equipment manufacturer with a global presence. These brackets were not only for structural-support purposes but were also visible in the end product, posing the need for their high strength and pristine uniform finish. Our white paint helped boost its aesthetics while protecting the bracket against indoor moisture and heat. In another instance, a home appliance brand contacted us for mounting plates finished in an appealing white color. These plates were visible within their upscale refrigerator line. Our team ensured an even covering of paint with minimum surface blemishes and excellent adhesion for a product both functional and good-looking.

Certain design considerations would enhance production of carbon steel stamping parts with a white paint finish. First, surface preparation becomes crucial. The metallic surface has to be cleaned and treated prior to applying paint, thereby ensuring a good bond. This process may include degreasing, phosphating, or sandblasting. Second, edge finishing is just as important. Sharp edges will cause paint to peel or chip. These corners should, instead, be rounded or smoothened for even paint application and durability. Third, control of paint thickness should be considered. Thick layers are prone to cracking and flaking, and thin layers do not provide proper protection. At pshardware, we apply just the right thickness for performance and aesthetics. Lastly, environmental condition exposure is very important. Parts exposed to sunlight or moisture could get recommendations for use of UV-stable or water-resistant paint formulations for longevity.

As a responsible manufacturer, pshardware is committed to minimizing our environmental impact. We use low emissions paints and energy-efficient ovens throughout painting. We recycle scrap metal or shavings produced in the manufacturing process, and use eco-friendly cleaning agents during surface preparation. Beyond being dedicated to quality and delivering superior products, pshardware will work toward positively impacting the shift toward greener manufacturing globally.

Carbon steel stamping components, especially those which are white-paint-finished, have unique codes: strength, protection, and good appearance. From automotive to construction, electronics, or consumer goods-different industries can benefit from the performance and appearance of their products with these components. pshardware combines high-quality materials with superior manufacturing techniques and tailored service to deliver carbon steel stamping parts that meet and exceed all requirements. Our white painting finishes are more than a coating. They are statements for durability, cleanliness, and design excellence.If you ask for a trusted partner to supply precision-engineered stamped parts with white-painted surfaces, then pshardware is your ultimate choice.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025