2025-05-21 12:38:21

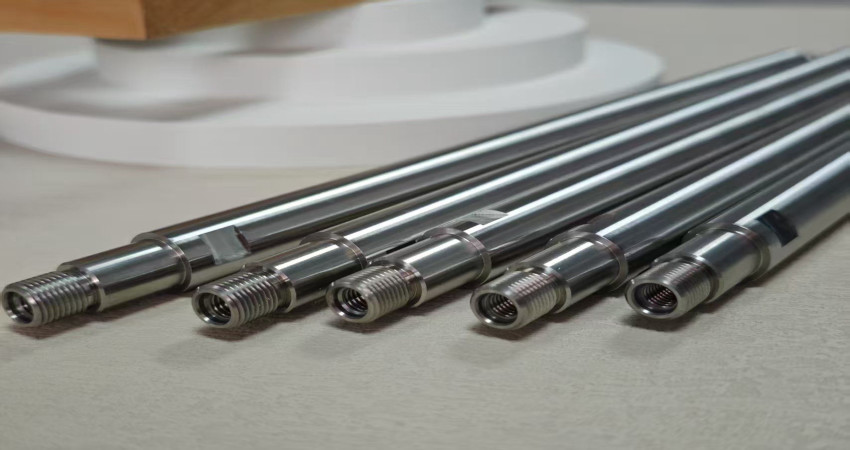

`Bronze has become the dominant professional manufacture when precision-engineered components must be built from strong and reliable materials. Bronze often outshines most materials in terms of durability, machinability, and excellent corrosion resistance; hence it finds extensive use within aerospace, automotive, marine, electrical, and heavy machinery industries. To convert bronze into highly accurate, functional components, manufacturers turn to CNC turning, which will ensure repeatable precision, low material waste, and consistent quality.Quality bronze CNC turned components are our gold signature in PSHardware, appealing through our partner manufacturer, Promostar. Do you seek high-quality bronze CNC machined components: clamps, inserts, bushings, pins, and much more, which have been engineered care and offered with speed? Then you're in the right placeLet us explore in detail why CNC turning is the perfect technique for bronze, what makes PSHardware and Promostar different from the rest, and how our comprehensive manufacturing services can help you benefit from them.

Bronze is an alloy of copper and tin as primary contents, although it can additionally carry other components, and is recognized to have some of the best mechanical properties. With an extensive application in producing parts that require corrosion resistance, strength, and a long leag, this one material comes with its specificities. To achieve geometries that are complex at the same time minimizing the wastage of materials during machining of bronze, high-precision machinery and programming skills are the requirements.

No Precision Like: CNC turning is unmatched in precision: it is computer-controlled machines that are precise to the micrometer following absolutely exact specifications. Human error generally associated with manual machining is eliminated, and repeatability results are dependent on CNC turning, particularly when producing thousands of identical parts. All Promostar CNC lathes are specifically developed for bronze and brass. This means they can carry out work ranging from simple cylindrical shapes to complex, multi-featured parts while upholding tight tolerances and minimal material waste. That translates to components that are both cost-effective and high in quality.

Speed and Scalability: Speed counts in high-demand industries. Fast production is offered by CNC turning with no compromise to accuracy. CNC machines are capable of running round the clock, with minimal supervision, producing thousands of units in record time, once a part design is finalized. With PSHardware's large-scale production capabilities, bulk orders can be easily fulfilled and delivered punctually. From hundreds to thousands, we do cater to runs of bronze components without turning a blind eye to strict deadlines, thanks to our CNC turning functionality.

Major Applications of Bronze CNC Turned Parts in Industries With the specific characteristics of the material and accuracy which CNC turning provides, bronze CNC turned parts are used in different industries. These are some of the most common applications:

Marine and Offshore Equipment: Bronze is naturally corrosion resistant, especially in saltwater conditions. Other applications of CNC-turned bronze parts include bearings, bushings, and pins used for shipbuilding, offshore drilling rigs, and marine propulsion systems.

Electrical and Electronics Industry: Because of bronze's conducive thermal and electrical properties, electrical connectors, terminals, and components of switchgear have been produced from this alloy. CNC turning will assure that these little yet very important components are produced with utmost precision.

Heavy Machinery and Construction: Bronze inserts, sleeves, and couplings machined through CNC turning provide thesign strength required in demanding applications and are generally wear resistant and capable of bearing heavy loads. This makes them fit for use in hydraulic applications, bulldozers, and excavators.

Aerospace and Defense: High-performance CNC-turned bronze parts are deployed in aircraft, military vehicles, and radar systems due to their reliability against environmental factors. Thanks to Promostar's high tolerance machining, all aerospace components meet stringent regulations specific to the industry

At PSHardware, we got to understand that quality is non-negotiable. That is why we have partnered with Promostar, one of the top manufacturers in brass, bronze, and CNC-turned parts, so that every product meets or exceeds all customer expectations. Partnering the best in engineering with quality customer service will deliver unmatched value through the entire process. Here is what sets Promostar apart in the CNC manufacturing industry:

1. Industry-Leading Precision and Accuracy: At the cutting-edge of high precision designs, Promostar's CNC turning is unmatched. These advanced systems can produce intricate bronze hardware that no manually operated machine could match. Whether as detailed inserts or large structural pins, Promostar machinery guarantees parts with exact thickness, diameter, and tolerance specifications.: The complexity of component geometries comes under CNC turning's accuracy, which makes it possible to execute flawlessly without this further processing or rework. With PSHardware and Promostar, you're guaranteed hardware that fits your assembly line perfectly, right out of the box.

2. Efficient and Repeatable Production: Over an extended large-scale production run, Promostar's CNC machines deliver high, consistent quality. Once a machine is set up for a part, it can be repeated thousands of times with deviances so close to zero that they are negligible. Repeatability is necessary when companies want thousands of components that are the same for either batch production or assembly of product. Of course, minimal material waste and optimized cutting strategies not only lead to savings on expensive raw material costs but also reduce production lead times—meaning you get more parts, faster, and for less.

3. International quality requirements are adhered to: Quality assurance is practiced thoroughly at Promostar, and its bronze and brass parts machining are manufactured following worldwide standards. It indicates that each CNC turned component supplied by PSHardware pass certifiably in those countries in regards to safety, strength, and performance. So, whether you are located in India, Europe, the United States, or anywhere else for that matter, you can rest assured that our bronze components do fulfill the requirements on mechanical and dimensional levels set forth in your respective country.

4. Capacity for Scalable Orders, Large and Small Counts: Whether it's a single item for a prototype run or a large order used for production, Promostar can scale itself to whatever the volume dictates. The latest lathes and tooling systems are in place at their facility, allowing them to manage more than one project at once without the fear of delay.: It is this flexibility that allows PSHardware to appeal to everyone, from start-up companies to well-established manufacturers, offering the same high level of service and product quality irrespective of the size of the order.

5. From Design to Delivery-Expert Support:PSHardware sells not just parts but solutions. The team's services encompass assistance in material selection, part design optimization, prototyping, and final delivery. We are ready to assist you should you require technical help or consultation on cost-effective manufacturing solutions.: The engineers at Promostar can even help you make CNC adjustments to your component design to reduce errors during production and ensure a smooth transition from design to finished product.

Below are some of your go-to bronze components we can offer:

• Bronze Clamps: Used in pipe fittings, construction, and marine applications.

• Bronze Inserts: Suitably applies to plastic injection molding, wood, or composite assemblies.

• Bronze Pins and Bushings: Necessary for automotive, aerospace, and machinery applications.

• Bronze Sleeves and Spacers: Applied in rotating or load-bearing functions.

• Custom Bronze Hardware: Crafted according to your exact specifications and engineering drawings. Every component can be tailored with respect to size, finish, and tolerances, depending on your specific needs. Ordering Bronze CNC Turned Parts Online Made Easy Getting started with PSHardware is as easy as filling in the inquiry form. No matter if you have a complete technical drawing or just a concept, we will work together with you from concept to product. When you order PSHardware parts made with the CNC skills of Promostar, you will benefit from:

• Cost-saving Prices: Minimizing raw material wastage and optimizing production.

• Quick Delivery Time: For urgent orders and bulk quantities.

• Quality Assurance: For thousands of units and never deviating from specifications. • Shipping Worldwide: To your door, guaranteed. Did I hear thousands of identical bronze parts? Just hoot and we deliver.

CNC turning changes the way bronze components are manufactured: it combines speed with precision and repeatability, all at the lowest cost. No matter if you are looking for heavy-duty mechanical inserts, pillow-like precision pins, or any form of corrosion-remitting bush; CNC-turned bronze parts from PSHardware and Promostar do give you performance to fall back on.PSHardware and Promostar team up to deliver a holistic experience: From CNC turning expertise to customer satisfaction. Every member of our team takes it upon themself that each of your components is done with perfection. So, when one says the best bronze CNC turned parts for consideration, the other side is PSHardware. Today, reach out to us and watch us give expression to your designs with unmatched quality and precision.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025