2025-06-04 12:20:46

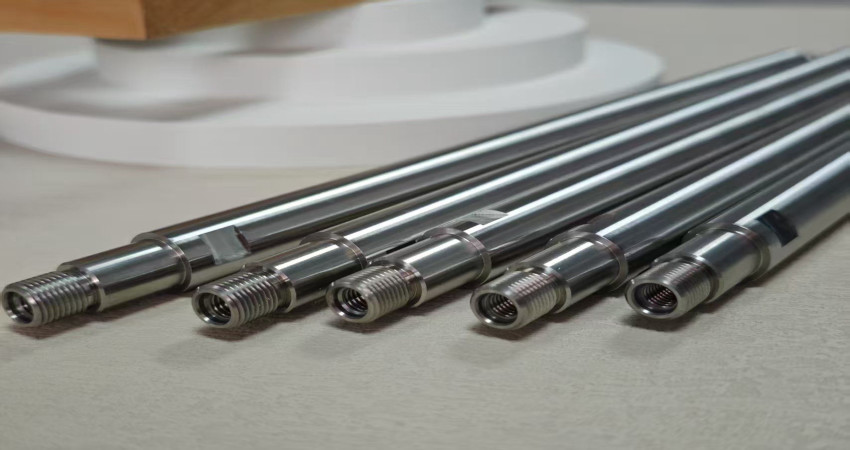

In the fast-evolving manufacturing world, the need for precision-engineered components has grown massively. Whether you deal with automotive, aeronautical, electronics, or medical industries, CNC turned parts directly affect the quality and performance of your products. With hundreds of suppliers located all around the world, how do you select the right CNC Turning parts manufacturer? This guide shall take you through everything you need to know in order to make an informed decision so that you can keep your production line running properly and without interruption. If you are planning to buy CNC Turning parts online, or are looking for a dependable CNC Turning parts supplier in China, read on for the factors that really matter.

Choosing a CNC Turning parts manufacturer is more than a simple procurement decision; it will become the foundation for a long-lasting partnership, affecting your operating efficiencies, product quality, and customer satisfaction. At best, a manufacturer of CNC turned parts will be precise, consistent, and reliable. The companies give value to tight tolerances, material selection, and their delivery schedules; so getting them wrong can lead to prolonged projects, redoing your work, rising costs, and damaged reputations. Good decisions are critical to sustainable growth and business success.

1. Look for Proven Industry Experience in CNC Turning

CNC turning parts Supplier with a long number of years in the threshold will be able to input experience as one of the most treasured assets. A CNC Turning parts supplier that has been in the sector for a long time will most probably have a very good hold on the turning processes, intricate geometry, and material behavior. They would then be in a better position to tackle problems, adapt your specifications, and maintain consistency in product quality. For example, pshardware has gained long-standing respect from all sectors requiring high-precision parts and technical support due to its experience. This inexperience usually equates into being better for process control and assuring quality, and for the most part being a smooth experience for the customers.

2. Assess Quality Standards and Certification

Well-respected CNC Turning parts suppliers will have strict quality procedures and hold internationally recognized certifications. ISO 9001 is a good indication of a company’s adherence to quality systems. Of course, AS9100 and ISO 13485 certifications become mandatory when dealing with the aerospace or medical sectors. Quality-oriented companies like pshardware will have multiple stages for inspection, material traceability, and documentation for all parts to ensure they are delivered according to set standards. To eliminate doubt and guarantee lasting confidence in the parts you get, ensure to check on these certifications when you buy CNC Turning parts online.

3. Evaluate Their CNC Machinery and Technical Capabilities

Modern turning requires modern tools. Advanced CNC machinery can achieve tighter tolerances and higher volumes with faster speed and accuracy while shaping complex geometries. Apart from that, an excellent CNC Turning parts manufacturer should possess multi-axis CNC lathes, high-speed machinery, and the capabilities to work with various materials. Even more importantly, however, they should balance the needs for producing small or large batches with consistently high levels of quality. Through investing in advanced CNC systems, pshardware has achieved scalability within its production capacity so that it can, with equal accuracy and professionalism, meet both large and small clients' needs.

4. Consider Engineering Support and Material Versatility

Different industries require different material characteristics, such as strength, corrosion resistance, machinability, and conductivity. This is where material versatility becomes essential. Whether you need stainless steel, aluminum, brass, or exotic alloys, your CNC Turning parts supplier should be able both to source and machine up to a wide range of materials. In that sense, pshardware goes another mile and provides engineering support to help you select an appropriate material according to design and performance criteria. This ensures the better performance of your components in actual use while saving time and cutting costs.

5. Select In-House Over Outsourced Manufacturing

When a manufacturer conducts production in-house, they have direct control over all production avenues, from materials through machining to inspection and packing. Outsourcing tends to leave room for delay, and miscommunication, and may breed inconsistency in quality. For these reasons, going with a CNC Turning parts manufacturer who maintains its own facilities would generally be safer and sounder. Thus, maintaining an integrated approach, pshardware is actively engaged in the efficient management of the whole production cycle internally, which guarantees quicker turnaround, enhanced quality control, and productive communication with customers. If you need help finding a dependable supplier who has full ownership of that process, this ought to be a priority in your selection.

The strategic advantage of using a CNC Turning parts supplier in China lies primarily in cost efficiency. Chinese suppliers usually have quite competitive prices, prompt lead times and can manage high-volume orders. But due diligence is important. Look for suppliers who have export experience, certifications, and a history of serving international clients. Today, pshardware is a global player with trusted partnerships with many leading CNC shops in China that help clients around the globe reap the benefits of affordability as well as quality. Thanks to the right Chinese partner, one can substantially optimize one's supply chain without compromising performance.

• Customization Capabilities are Must-Haves

Every project has its own requirements. Solutions that are generic and myriad rarely work well for precision manufacturing. Your CNC Turning parts supplier should offer customization capability by way of prototyping, reverse engineering, and rapid designs to alter on the designs of parts. Your visualization translated into a finished product with exact specifications if you're working with a CAD drawing or a physical sample: This can be ensured by a supplier. At pshardware, the team works closely with clients from start to finish from design review to final production all of which ensures that reworking is minimized, ensuring smoother execution of your projects.

• Delivery Times and Logistics Support Shouldn't Be Missed

On-time delivery value equals quality. Not receiving CNC parts on time can stop production lines entirely, cause disruptions in schedules, and reduce your net revenue. Choose a CNC Turning parts distributor who values punctuality and has good logistics partnerships to deliver the products safely and quickly. These suppliers would offer real-time tracking, very efficient packaging, and flexible shipping options. When ordering CNC Turning parts online from pshardware, one enjoys global shipping coverage, secured transit, and a highly responsive team that is professional in dealing with customs documentation and tracking.

• Responsive Customer Service Makes a Difference

In addition, it has a lot to offer when you partner with a CNC supplier for its strong support team. The ideal CNC Turning parts supplier would be proactive in addressing your queries, transparent in their communication, and will support even after delivering the order. Good customer service can alleviate most difficulties you might encounter along the way-whether for technical clarifications, updates on production, or help with reordering. Customer satisfaction is paramount at pshardware. The 24-hour assistance from dedicated support staff enables fast resolutions from technical or delivery-related concerns, making them a partner you can count on.

Indeed, digitization transforms the industrial supply chain, and many professionals now buy CNC Turning parts online. This method provides fabulous convenience-offering simple browsing, instant quotations, and transparent product information. Reputed platforms such as pshardware.com provide all the necessary security for clients to place orders, track shipments, and download essential documentation at one place. buying online cuts down on procurement time and the paperwork involved. It allows more attention to focus on production than vendor management. Just be sure to buy from verified suppliers with reviews, good return policies, and certified product listings.

Choosing the best CNC Turning parts manufacturer is not merely a technical process-it is researching and knowing what goes into it. Understand their expertise level, machinery capabilities, logistics support, and after-sales service. All these parameters play a varying degree in your decision-making process. pshardware being a reliable name for CNC turned components across industries has truly committed itself to quality and global sourcing capabilities with a customer-first approach.

Whether you want to buy CNC Turning parts online, collaborate with a reliable CNC Turning parts supplier in China, or need a full-service CNC Turning parts distributor, pshardware offers the precision, support, and scalability to meet your requirements. Smart decisions should start today, and the manufacturing business should receive the exact partner it deserves in precision.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025