2025-11-07 10:47:55

Precision and grip are two very crucial aspects of a product in the world of industrial manufacturing as they define the quality and performance of a product. No matter it is a screw, a bolt or a fastener, the finishing texture may be the difference in use. It is here that Diamond Shaped Knurling comes to the rescue as an innovator. This form of knurling is recognized as having a better grip, strength and aesthetics with preference being given in several industries such as automotive, aerospace, machinery and electronics.PSHardware is a company that deals with the provision of Precision Diamond Knurling Services that is of unquestioned uniformity and quality. Being a Custom Diamond Knurling Design Manufacturer, we offer custom knurling designs that can satisfy the requirements of every industry. But what is it, exactly, that Diamond Shaped Knurling? Why are you supposed to take it into consideration in your next project? Let’s explore in detail.

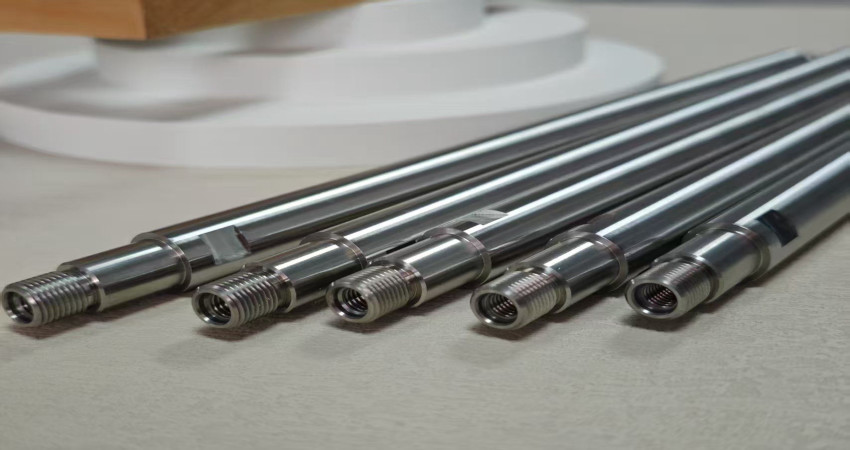

Diamond Shaped Knurling is a decoration made on the surface of metals, mostly screws, bolts and other fasteners. This pattern consists of minor, crossing diagonal lines creating diamond-like impressions. This texture does not only provide a good grip, but also provides a professional and aesthetic appearance on the final product.The Knurled Diamond Pattern: This is a process which is done with special knurling tools and a lathe machine. These instruments stamp or engrave the diamond pattern into the metal surface producing an identical pattern which is esthetically and practically advantageous.

The major merit of Diamond Shaped Knurling is the high quality of grip. The Knurled Diamond Pattern offers various contact points due to the intersecting lines and this has made it easy to handle the screws, bolts, and other parts even during oily or slippery conditions. This renders Diamond Knurling Fasteners suitable in mechanical assemblies, tool handles, and sensitive equipments where a firm grip is very important. The anti-slip surface does not only make it more useful, but also reduces the risk of errors in operations in the course of assembly and maintenance.

Visual finish of a product can be used as a measure of quality workmanship. Diamond Knurling Design provides metal parts with a smooth sleek and professional appearance, which makes them attractive and more valuable in the market. The symmetrical shape of the diamond design is a good reflector of the light and creates the illusion of a high-quality and premium product. In the PSHardware, we have Precision Diamond Knurling Services that help in ensuring that each piece is of the highest quality in the way it is designed and finished. We know that, aesthetics are equally crucial to functionality and are particularly relevant in such sectors as automotive and consumer electronics, where the looks are equally as important as the performance.

The higher torque of Diamond Shaped Knurling of Screws and Bolts is one of the most viable advantages in this case. The rough surface enables more interaction between the connector and the tool, which will provide a more compact fit, and less slipping when tightening. This high torque performance is especially important in high vibration machines like engines, heavy machinery, and industrial equipment, where the safe fastenings are required to ensure safety and performance.

Knurling does not only give the surface a texture it also makes the surface stronger. During the Diamond Knurling Design process, the metal is slightly compressed and this enhances the resistance of the metal to wear and surface damages. This renders Diamond Knurling Fasteners more robust as compared to the smooth-surfaced ones. Diamond Shaped Knurling will guarantee long-term durability regardless of it being constant tightening, being exposed to the environment, or friction. In PSHardware, our sophisticated production processes are able to add to the life and the durability of your components and enable them to fit in the rigorous usage.

Each industry sets its own demands. As an example, the aerospace industry requires exceptionally light but high grip bolts, whereas the automotive industry requires knurled bolts that are corrosion resistant, heat and vibration resistant.And that is where we have the strength of our specialist as a Custom Diamond Knurling Design Manufacturer. In PSHardware, customized Diamond Knurling Designs are provided to suit your required size, materials and performance. Our engineers work with clients in efforts of coming up with Diamond Shaped Knurling patterns that can be used to the latter and that meet precise industrial requirements.

The Diamond Shaped Knurling is very versatile and is used in numerous products such as:

• Screws and Bolts: Enhanced mechanical assembly gripping and torque.

• Tool Handles: Improved manual tool control and fine instruments.

• Aerospace Components: Light and strong grip surfaces.

• Medical Devices: Knurling of surgical instruments in high precision.

• Car Furniture: Strong and appealing parts.

• Electronics: Smooth design and functional connector and knob grip.

Due to the flexibility, Diamond Shaped Knurling has become an industry standard of enhancing functionality and appearance.

In the industrial setting, ease of disassembly and assembly can save a lot of time and effort. Diamond Knurling Screws have superior manual manipulation thus easy to either tighten or loosen without falling. This is especially useful in the case of the technicians and maintenance workers who handle miniature, more complex parts in their day-to-day interactions. In the case of Diamond Knurling Fasteners, PSHardware makes sure that the users always have a smooth, efficient, and error-free assembly.

Diamond Shaped Knurling has other significant benefits which include the ability to fit in numerous materials. The Knurled Diamond Pattern is applicable to stainless steel, aluminum, brass or titanium to provide a better grip and texture. Our Expert Diamond Knurling Services at PSHardware will be provided to operate with various alloys and metals, and all the materials of the types will be of the same quality. This flexibility gives manufacturers the option to knurl various components in a consistent design and performance.

PSHardware is proud of providing Precision Diamond Knurling Services with highly advanced machinery and high-quality controls. Each part is thoroughly inspected in order to make sure that the Diamond Knurling Design is completely uniform and aligned over the entire batch. Our technicians have state of art CNC machines and knurling tools to ensure consistency in the pressure and depth to produce perfect patterns. Such care takes care of the detail and hence, your Diamond Shaped Knurling of Screws and Bolts is not only up to your performance standards, but also beyond them.

The idea of investing in Diamond Shaped Knurling is not only limited to the quality but also cost efficiency. Knurled components have a tendency of lasting longer and working well with stress hence eliminating frequent replacement and maintenance. This comes to mean a huge saving in the long run to both the manufacturer and the end user. Furthermore, in case of partnership with PSHardware, you receive the affordable Custom Diamond Knurling Design Manufacturing without having to sacrifice on quality or accuracy.

PSHardware, being a reliable Custom Diamond Knurling Design Manufacturer, has several years of experience, innovativeness, and accuracy with respect to each project. Here’s what sets us apart:

• High-tech Machinery: CNC knurling technology.

• Precision Designing: Precision Diamond Knurling Designs to meet each application.

• Close Quality Control: Each work is carefully inspected.

• Skilled Workforce: Team of experienced engineers who have decades of experience in knurling techniques.

• Global Standards: International quality manufacturing operations.

PSHardware has the answer to your Diamond Knurling Screws, Fasteners and even custom parts that are durable, attractive, and perform well.

The benefits of Diamond Shaped Knurling are not exclusive to the texture, it is a functional improvement, which makes the product easier to hold, and last longer. Knurled Diamond Pattern is used in screws and bolts, fasteners, handles and in all applications.The Precision Diamond Knurling Services of PSHardware are the best combination of both technology and craftsmanship. We are the preferred company when it comes to Custom Diamond Knurling Design Manufacturer across all industries and that is because we believe in quality, customization and innovation. When you are searching to take your product design and performance to the next level, then it is time to invest in Diamond Shaped Knurling at PSHardware where precision and perfection are combined.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025