2025-04-29 06:15:28

In the world of contrastingly competitive global industrial manufacturing, precision, quality, and reliability are non-negotiable. They are an important set of components to various industries. In this group, brass CNC turned parts excel in their durability, conductivity, and machining quality. It is critical to find a reliable supplier who does not hesitate to yield high-grade brass CNC turned parts, and here's where Promostar really stands out. Customers worldwide who couple up with Pshardware will now import brass CNC turned parts of Promostar with full assurance.In this blog, we shall perform a deep dive into the importance of brass CNC turned parts, why Promostar tops the list among brass CNC turned parts manufacturers, and how Pshardware plays its role to facilitate a smooth, safe, and efficient buying experience.

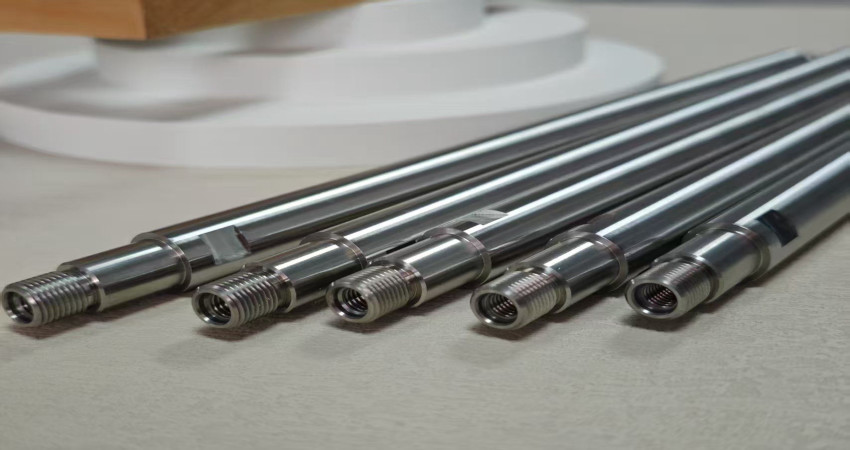

Brass CNC turned elements are one of the vital elements introduced by an advanced method called CNC turning. In CNC turning, the computer spins the brass material on the lathe, and special cutters carve the material to specific critical dimensions and geometries. In each produce quantity, highly accurate, repeatable, and consistent parts are assured. From hairline connectors in electronic equipment to heavy duty marine equipment that will be well served with CNC turned parts, such parts interface exponentially with the functionality and efficiency of contemporary engineering and innumerable manufacturing processes. Brass stands as the best base material in the development of such parts because of brass's hallmarking features: machinability, corrosion resistance, a nice appearance, and excellent thermal and electrical conductivity. Once aware of what brass CNC parts look like, and understand pros of brass great physical properties being put into use for so many applications, the enlightened decision could easily be made in component sourcing using me as a systematic guide which tutorial reflects the initial impression ascribed to the enlightening journey.

Apart from being an attractive alloy, brass presented mechanical, thermal, and chemical loyalties, making it an ideal material for CNC turned parts.

1. Extraordinary Machinability: Saves Money and Time: Brass, when machined, is classified as one of the most easily machinable metals before being converted into a final shape. This results in low-energy tools and minimal time required to create goods, which result in faster production cycles and fewer tool damages, therefore reducing the cost of their respective fabrication. This ability of machining very complex parts very quickly and accurately makes brass the most suitable metal for various applications where high-precision components have to be delivered fast.

2. Projection for Outstanding Corrosion and Wear Resistance During Long-Term Equipment Operation: Mainly and unlike other metals, brass has natural resistance to corrosion and tarnishing. This quality empowers brass CNC turned parts to retain their strength and also keep their appearance right, even in rough environmental conditions, say lee-coast maritime applications and some other physical-apparatus environments. Eventually, brass with superior memories holds the life of components through a similar enforced hierarchy upon a bare-minimum one-time wear, thereby promising more logarithmic payback over time.

3. Possessing Outstanding Thermal and Electrical Conductivity Thanks to Brass: Brass provides unmatched comfort conductivity in electric and electronic applications, ensuring low resistance during the transfer of energy. Acting as a moderator of temperature change, brass possessing excellent thermal properties allows for components that are subjected to long-term temperature fluctuations. Thus, brass CNC turned parts are the most suitable solution for industries like automotive, aerospace, and telecommunications where high-precision structures are required.

4. Arises as a True Power, Including Visual Appeal, for High-End Applications: Essentially, apart from its mechanical strength, brass renders a natural and shiny appearance, enhances the beauty of components. Herein a situation like when the eye counts, there is an amazing collection of them-in those kinds of fittings-carried by brass.

Remember that wheeler-dealing objective of precision and reliability that implies continuous quality, and many reputable manufacturers emerge out. Pride among global manufacturers lies with them. Promostar spontaneously depicts itself on the world stage as one of the proud manufacturers known for their highest quality-brass CNC turned parts within internationally recommended standardization efforts.

1. A Presentation of Cutting-Edge CNC Machining Facilities:Promostar, with all cutting-edge machinery, brings world-class precision to your brass CNC turned parts. Multi-axis CNC lathes are put to operation in Promostar's production facilities, which is further supported by the latest technology in the CNC machine parts creation. Custom machining of parts may come in with multiple design schemes, engineering tolerances, and finishes without a single blemish-grade one-off. Henceforth, whether manufacturing demands range from mere fittings to those of highly complex under structures — once you tap the manufacturing possibilities of Promostar — it's Hasta la Vista Orange.

2. From Scratch to Completion: Entire Devoted, I Mean: Quality control is just synonymous with most things owned upon Promostar, right from the onset of mass production. The supply chain of every quantity of brass promotes such production, creating a dedicated team of vigilant, tested suppliers, ISO certifications enforced with designated equipment for checks, quality laboratory training, knowing the key stress points, testing, and endorsing them during daylight. Your total line of sight at the turn of every machine is real. If time ever necessitates a flashback, your resources would remind you of Promostar.

3. Critically Engineered Pairs: Indeed 3-D Design and Rapid Prototyping Services-All of Which Is Tailored to Meet Specific Customer Needs: Promostar not only customizes: they also create some of the best-designed CNC turned parts that fit-the needs for and become interlocked with the customer's application forms. Promostar will help you in terms of quick prototyping of your designs so that they enable efficient testing of ideas-development cycle further draws near to get fast-feedback-and market release of a brand-new product.

4. They Successful Embody Reliability as Then Employs Global Distributors Thus provide Global Delivery: An instance is an opportunity cost we cannot afford. There, of course, is the realization of how Time is Money in today's industry. In line with this, Promostar delivers short lead times and worldwide shipping due to efficient planning of production and a well-organized logistics network. By this, you may be guaranteed that each and every assignment you want to be executed will be suitable for its application and will not run late.

5. Are Used and Trusted in Many Industries for Various Applications:Promostar extends its credentials to several sectors, automotive, aerospace, defense, medical devices, consumer electronics, and renewable energy. With agility and deep engineering expertise, they make brass CNC turned parts that are suited to each sector's particular needs.

While Promostar manufactures excellence, Pshardware ensures that excellence reaches you seamlessly and efficiently. Acting as an authorized distributor of Promostar's precision components, Pshardware combines the strong and trustworthy purchasing confidence with world-class customer support.

1. Guaranteed Authenticity and Quality: With Pshardware, you are guaranteed to receive 100% genuine parts from Promostar. All products are directly sourced from the manufacturer, meaning there are no risks of counterfeits, quality uncertainties, or unauthorized sellers.

2. Technical Insight and Tailored Support for You and Your Projects: The own team of Pshardware consists of highly experienced engineers and procurement specialists that comprehend the technical complexities of CNC components. They provide consultations tailored to help you select the most suitable brass parts for your application, ensuring the best performance, durability, and cost-efficiency.

3. Pricing that Is Competitive to Optimize Your Investment:Pshardware is able to provide factory-direct pricing through its close partnership with Promostar. All your sourcing needs for either small quantities or mass buys are, on top of that, assured highly competitive pricing without compromising on quality nor reliability of service.

4. An Online Store for Your Full Convenience: It is effortless to order online with Pshardware. Using their well-designed e-commerce platform, you can view product catalogs with product details, upload your specifications, request a custom quote, and place your order-all on your computer or mobile device. With tracking and communication features embedded, you'll be kept updated at every order step.

5. After-Sales Service that Will Be Helping You with Your Activities:Pshardware's dedication to customer satisfaction does not finish upon delivery. They provide thorough after-sales services, which include installation support, troubleshooting, and even easy reordering. Their main objective is to become a long-term partner ensuring success within your supply chain.

Pshardware has simplified the order placement process to ensure every custom requirement, even the most complex, proceeds smoothly.

Step 1: Search the Online Catalog: Visit Pshardware's official website, where you’ll find the Brass CNC Turned Parts section. Check through the catalog structured with detailed specifications regarding material grades, dimensions, tolerances, and applications.

Step 2: Describe Your Requirements: Either search with filters to identify standard parts that might be of interest to you or upload drawings highlighting the custom parts you require. The facility supports various formats to communicate your design intent clearly.

Step 3: Request a Customized Quote: Submit an RFQ (Request for Quotation) through the portal for any particular needs or bulk demand. Their team will analyze your specifications and revert with a thorough offer including details of prices, lead times, and supplementary suggestions.

Step 4: Confirm and Complete Your Order: When you are satisfied with the quote, accept it, proceed to your secure checkout via Worx, where they will provide you with payment options that match your business practices best. Step 5: Receiving and Tracking the Shipment: Once confirmed, you will start getting real-time tracking updates on your order, ensuring transparency in the shipment process. With Pshardware's robust logistics network, the parts will reach you intact and right on time.

Promostar's brass CNC turned components ordered through Pshardware have been essential in several real-world projects:

• Automotive sector: Precision brass fittings and connectors that enhance safety of automobiles and sensor technologies.abrasive.

• Electronics sector: Brass components with high conductivity for enhancing the efficiency and reliability of consumer electronics.

• Medical devices: Corrosion-resistant brass parts, meeting standards of hygiene, and delivering a long-term performance.

• Telecommunication: High-speed signal durability from brass connectors across vital links of communication infrastructure.

• Marine equipment: Corrosion resistance of brass makes it suitable for parts of machines that are undersea and exposed to salt.

No matter what Promostar parts you engage through Pshardware, you can be sure you have the best tool fanning your innovations on the cutting edge.

In the most precarious modern manufacturing environment, every component counts. When you select Promostar for your brass CNC-turned parts, you choose a manufacturer focused on precision, quality, and innovation. Doing so through Pshardware guarantees that you get authentic parts, that you can speak to an expert about your project, get the best prices, and a seamless online shopping experience. Trust Promostar and Pshardware for performance, reliability, and convenience. Check out the catalog today and take your manufacturing projects to the next level.

Date : 31 Dec 2025

Date : 27 Oct 2025

Date : 16 Oct 2025

Date : 11 Oct 2025

Date : 20 Sep 2025

Date : 13 Sep 2025

Date : 06 Sep 2025

.jpg)

Date : 31 Jul 2025

.jpg)

.jpg)

Date : 24 Jul 2025

.jpg)

Date : 12 Jul 2025

.jpg)

Date : 02 Jul 2025

Date : 24 Jun 2025

Date : 23 Jun 2025

.jpg)

Date : 14 Jun 2025

.jpg)

Date : 10 Jun 2025

Date : 31 May 2025

Date : 16 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 11 Apr 2025

Date : 09 Apr 2025